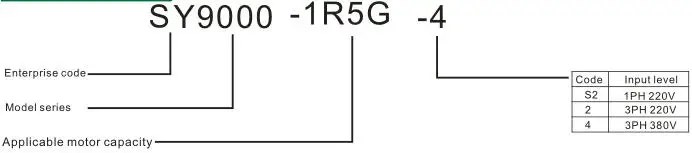

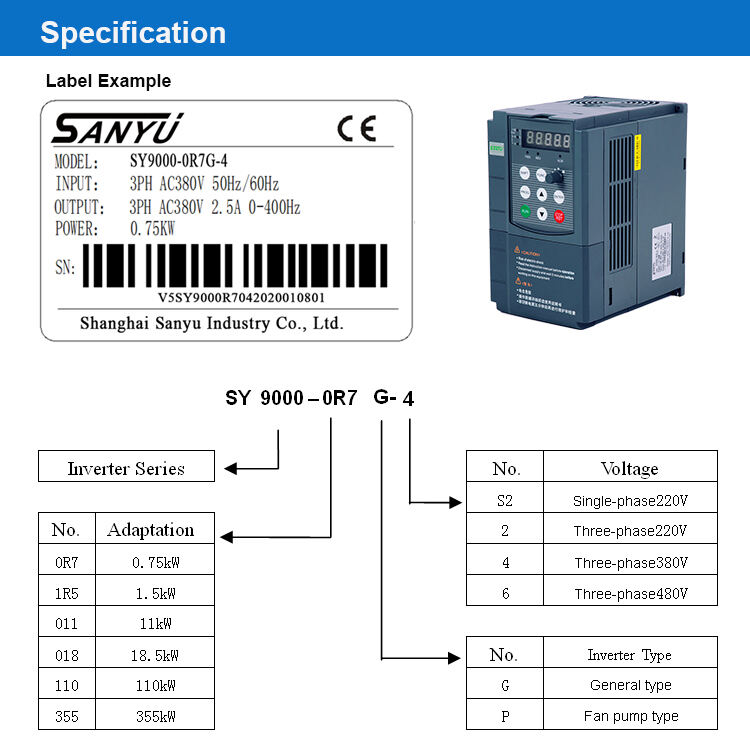

SY9000 frequency inverter vsd vfd frequency converter 3 phase 380V 110KW high power frequency drives voltage regulator

- Overview

- Inquiry

- Related Products

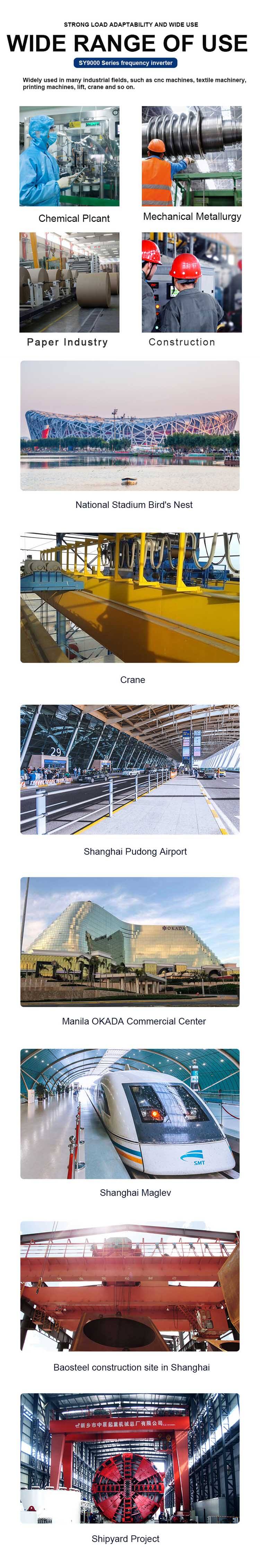

Four control modes: V/F control with PG, V/F without PG, open loop vector control, close-loop vector control.

Input voltage: 220V~240V+/-15%,3 AC 380V~460V +/-15%.

Overload capacity: 150% for 60s, 180% for 10s, 200% for 3s.

Start torque:0Hz/150%(SVC), 0Hz/180%(FVC).

Speed adjust range:1:1000(FVC),1:100(SVC).

Speed control accuracy:+/-0.02%(FVC), +/- 0.2%(SVC).

Speed control response:<3.5ms>

Modbus, profibus and CANopen communications are optional .

2 channels AI and 2 channels AO.(0-20mA,0-10V)

SANYU

The SY9000 regularity inverter from SANYU is an item is top-of-the-line if it comes to regulating voltage and transforming regularity in 3 period 380V equipment up to 110KW. This energy high drive converter is built to provide maximum efficiency and dependable performance even in demanding applications.

The SY9000 regularity inverter is beneficial at managing the speed of motors with accuracy, which helps to truly save power, reduce deterioration, and expand living of the equipment along with its higher rate design. The SY9000 frequency inverter from SANYU could be the perfect solution whether you need to run a motor-driven pump, fan, conveyor, or simply just about any gear that requires variable rate control.

One of many great things about the SY9000 frequency inverter is its user-friendly program. The inverter is sold with a display that just digital, provides real-time feedback in the status linked to the gear, along with clear instructions on how best to adjust the numerous parameters to suit your particular needs. It’s made by this feature is particular easy to arranged and operate the inverter also if you are unfamiliar with frequency converter technology.

The SY9000 frequency inverter also boasts advanced safety features that can protect both the gear in addition to users. The inverter is sold with overvoltage, under-voltage, overcurrent, overheating, and circuit is brief, which assist to avoid problems for the apparatus and guarantee safe operation all the time.

Another benefit of this operational system is its compact and construction that's robust. The SY9000 regularity inverter is built to withstand surroundings which are harsh can operate at conditions starting from -10°C to 50°C. The inverter is sold with a high internet protocol address, meaning it is protected against dirt and water ingress.

SY9000 series frequency inverter frequency converter vsd vfd high power frequency drives voltage regulator

1. Features:

Item |

Specifications |

|

Basic function |

Control system |

High performance of current vector control technology to realize asynchronous motor control |

Drive performance |

High efficiency driving for induction motor |

|

Maximum frequency |

0~500Hz |

|

Carrier frequency |

0.8k~8kHz; the carrier frequency will be automatically adjusted according to the load characteristics |

|

Input frequency resolution |

Digital setting: 0.01Hz |

|

Control mode |

Open loop vector control(SVC) |

|

Start-up torque |

Type G:0.5Hz/150%(SVC);0Hz/180%(FVC) |

|

Speed range |

1:100(SVC) 1:1000(FVC) |

|

Speed stabilizing precision |

±0.5%(SVC) 0.02%(FVC) |

|

Torque control precision |

±3%(FVC) |

|

Over load capability |

G type: rated current 150% -1 minute, rated current 180% -3 seconds; |

|

Torque boost |

Auto torque boost function; Manual torque boost 0.1%~30.0% |

|

V/Fcurve |

Linear V/F, Multi-point V/F and Square V/F curve(power of 1.2, 1.4, 1.6, 1.8, 2.0) |

|

V/F separation |

In 2 ways: separation ,semi separation |

|

Acc. /deccurve |

Straight line or S curve acceleration and deceleration mode |

|

DC brake |

DC brake frequency: 0.00Hz to maximum frequency, brake time: 0.0s to 36.0s, and brake current value: 0.0% to 100.0%. |

|

Jog control |

Jog frequency range: 0.00Hz~50.00Hz. Jog acceleration/deceleration time 0.0s~6500.0s |

|

Simple PLC and MS speed running |

It can realize at maximum of 16 segments speed running via the built-in PLC or control terminal |

|

Built-in PID |

It is easy to realize process-controlled close loop control system |

|

Auto voltage regulation (AVR) |

It can keep constant output voltage automatically in case of change of network voltage |

|

Over-voltage/current stall control |

It can limit the running voltage/current automatically and prevent frequent over-voltage/current tripping during the running process |

|

Quick current limit |

Minimize the over-current fault, protect normal operation of the inverter |

|

Torque limit & control |

"Excavators" characteristics, automatically limit torque during operation, prevent frequent over-current trip; Closed loop vector mode can realize the torque control |

|

Personalized |

Instantaneous stop non-stop |

When instantaneous power off, voltage reduction is compensated through load feedback energy, which could make inverter keep running in a short period of time |

Rapid current limit |

To avoid inverter frequent over-current fault. |

|

Virtual IO |

5 groups of virtual DI,DO to realize simple logic control |

|

Timing control |

Timing control function: set time range 0Min~6500.0Min |

|

Multiple motor switch |

2 groups of motor parameter, which can realize 2-motor switch control |

|

Communication support |

Standard modbus:RS485 |

|

Multi-encoder support |

Support difference, open collector, rotary transformer, etc. |

|

Running |

Running command channel |

Three types of channels: operation panel reference, control terminal reference and serial communication port reference. These channels can be switched in various modes. |

Frequency source |

There are totally eleven types of frequency sources, such as digital reference, analog voltage reference, analog current reference, pulse reference, MS speed, PLC, PID and serial port reference. |

|

Auxiliary frequency source |

11 kinds of auxiliary frequency source which can flexible achieve auxiliary frequency tuning, frequency synthesis |

|

Input terminal |

Standard: There are 6 digital input terminals, DI5 can be used as 100kHz high speed input pulse. 2 analog input terminals, AI1can be used as 0-10V voltage input, AI2 can be used as 0-10V voltage input or 0~20mA current input. |

|

Output terminal |

Standard: 1 digital output terminals, Y1 is high-speed pulse output terminal (can be chosen as open circuit collector type), support 0~10kHz square wave signal; 2 relay output terminal; 2 analog output terminals, support 0~20mA output current or 0~10V output voltage; |

|

LED display |

Realize parameter setting, status monitoring function |

|

Keyboard potentiometer |

Equipped with keyboard potentiometer or coding potentiometer |

|

Key lock & function selection |

Realize button locking, define operation range for part of buttons to prevent operation fault. |

|

Protection function |

It can implement power-on motor short-circuit detection, input/output phase loss protection, overcurrent protection, overvoltage protection, under voltage protection, overheating protection and overload protection. |

|

Optional parts |

Differential input PG card, OC input PG card, sin & cos endorser PG card |

|

Environment |

Using place |

Indoor, and be free from direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapor, drip or salt. |

Altitude |

Below 1000m |

|

Ambient temperature |

-10 ℃ to +40 ℃ (Derating use when under ambient temperature of 40 ℃ to 50 ℃) |

|

Humidity |

Less than 95%RH, without condensing |

|

Vibration |

Less than 5.9 m/s2(0.6g) |

|

Storage temperature |

-20℃~+60℃ |

2. Product Show

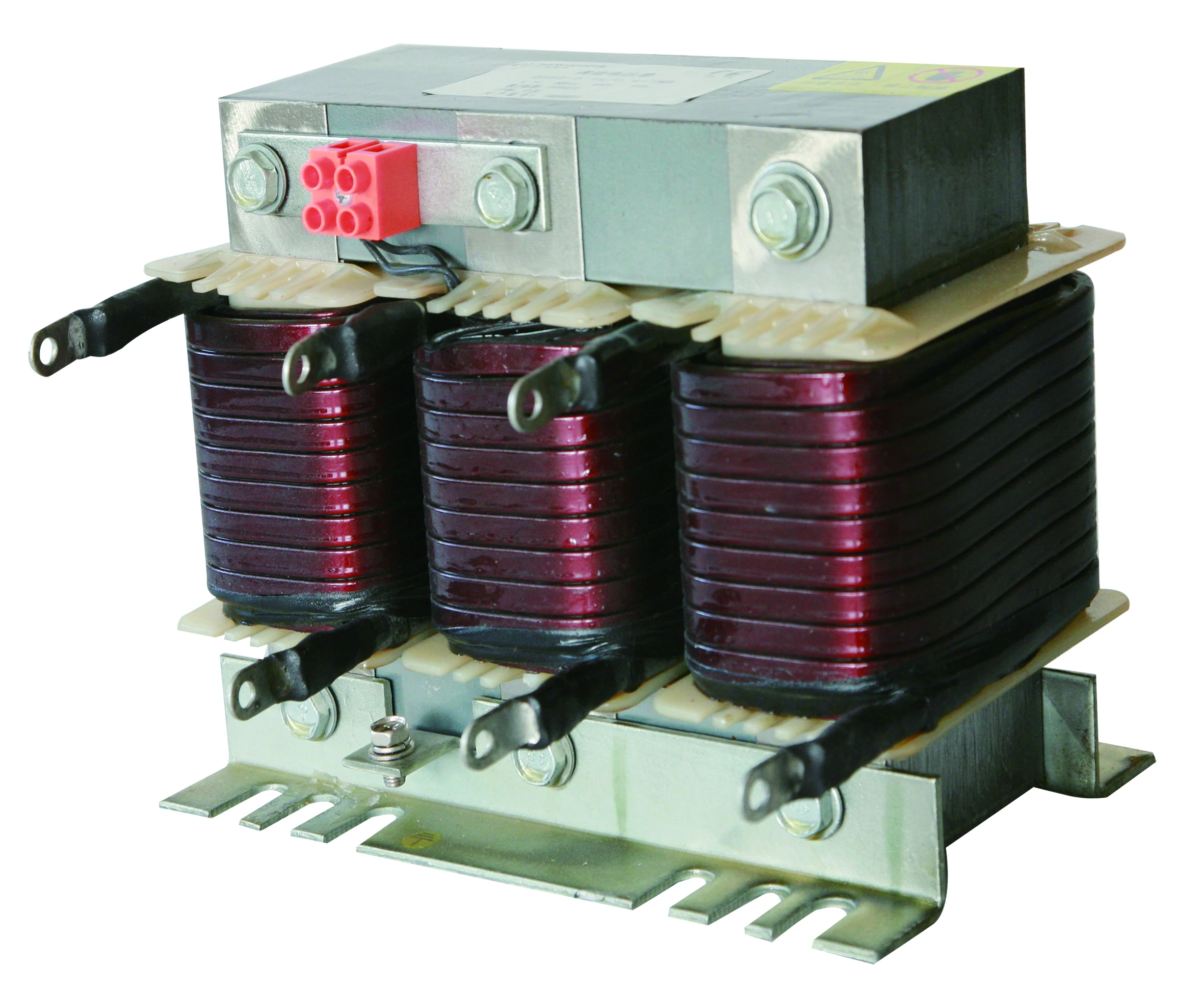

3. Main Components:

4. High Quanlity Control

5. High Reputation:

6. Packing and Delivery:

7. Payment:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS